Engine Inspection and Reassembly

| Two engines came to us from MFI in Florida. They are used on the mission's Cessna 310 which makes trips to Haiti and the Bahamas for emergency trips were it wouldn't be prudent to take the much larger DC-3. The engines required a tear down inspection and so I got the experience of working on the left engine. During the process, we disassembled the engines, took measurements, replaced parts that were no longer acceptable and cleaned everything really well. These pictures start with the reassembly phase and go all the way to the engine run. The movie at the end shows a very small part of the engine run we did yesterday. Thankfully the engine did quite well and we were pleased with the performance and numbers we saw. Now all that is left is to finish the other engine and test it, then reinstall them on the 310.  |

| Crankshaft after inspection and polishing. |

|

| Left side of crankcase with freshly installed cylinder base studs. |

|

| Crankshaft and camshaft getting ready for installation. |

|

| Crankcase ready to receive bearings. |

|

| Crankshaft with connecting rods and gear installed. |

|

| Crankshaft and camshaft installed along with oil transfer collar and idler gear. |

|

| Case halves together! |

|

| Another view of case halves. |

|

| Engine is ready for cylinder installation. |

|

| The first of six is installed |

|

| Cylinders installed! Ready for torque...all 58 bolts and nuts. |

|

| Here is the view from the bottom showing the inside of the crankshaft. |

|

| Fuel injection system going on now. |

|

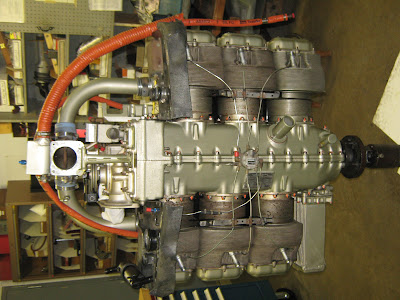

| Almost done! |

|

| Test stand installation. |

| ||||||

| Installed with propeller and almost ready! |

What an encouragement it is to see a successful end to this project so it can return to service for God's work. It looks like I may get to help install the engines as part of a rapid response trip in a couple of weeks. I look forward to updating you on that process.

Thanks for your prayers and support!

Ben

Comments

Post a Comment